NSI 3D IMPLANT

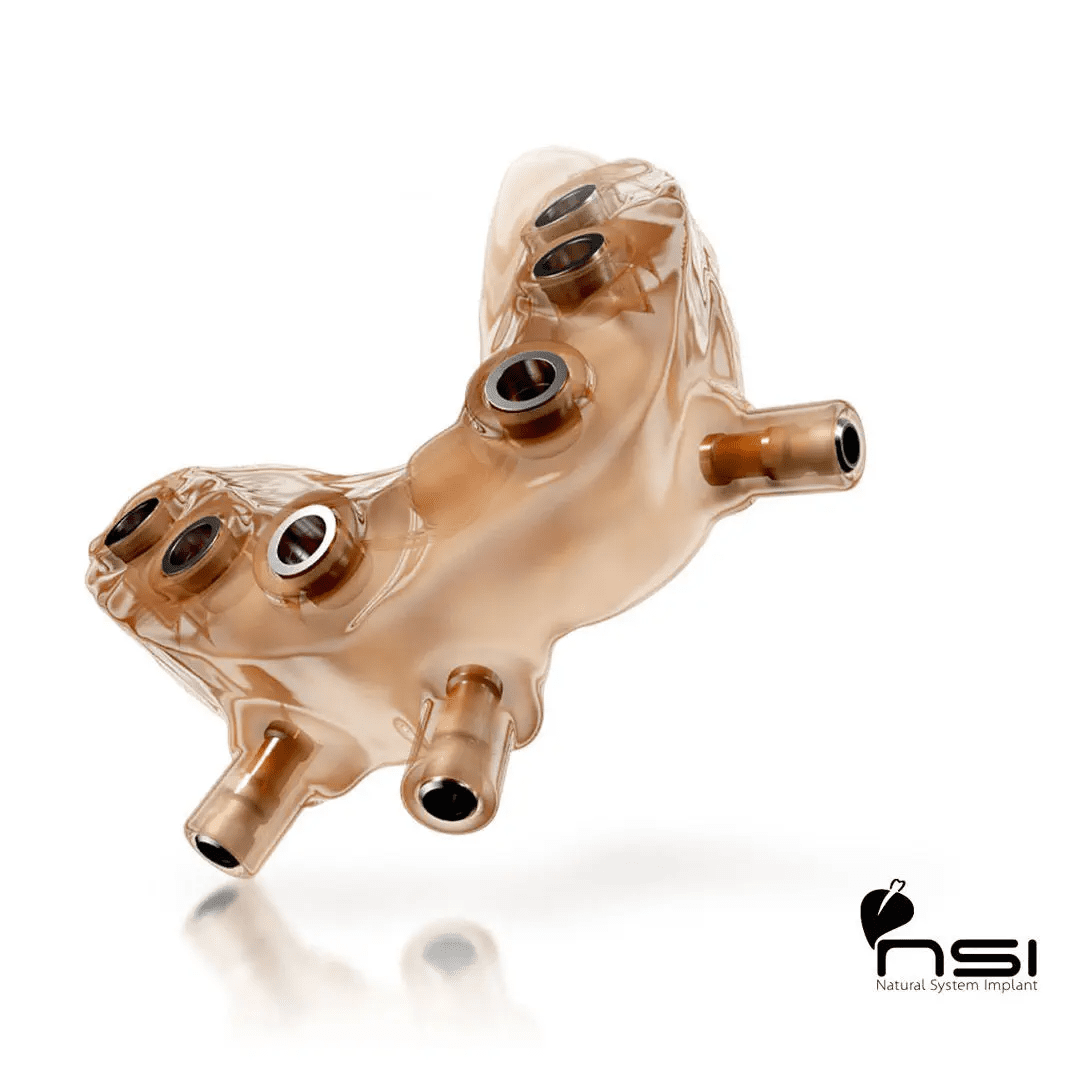

MX HYBRID – THE PERFECT FUSION IMMEDIATE LOADING WITHOUT LIMITS

NSI 3D IMPLANT

Request a Call Back

- Ask a Question

NSI 3D IMPLANT

Ask a Question

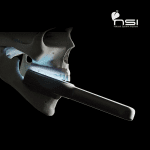

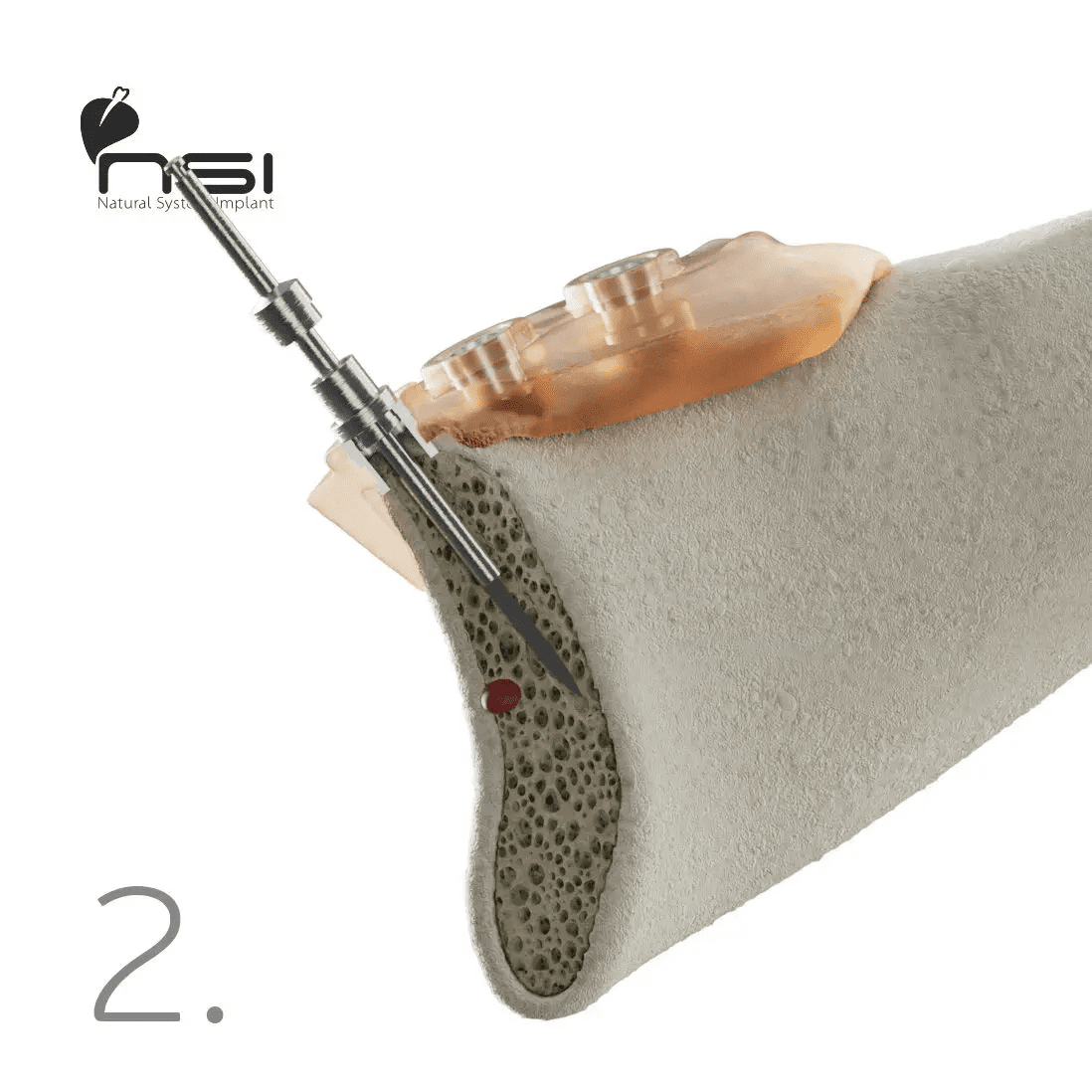

THE MINI-INVASIVENESS

A single drill to insert the implant.

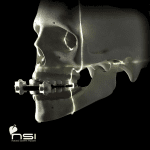

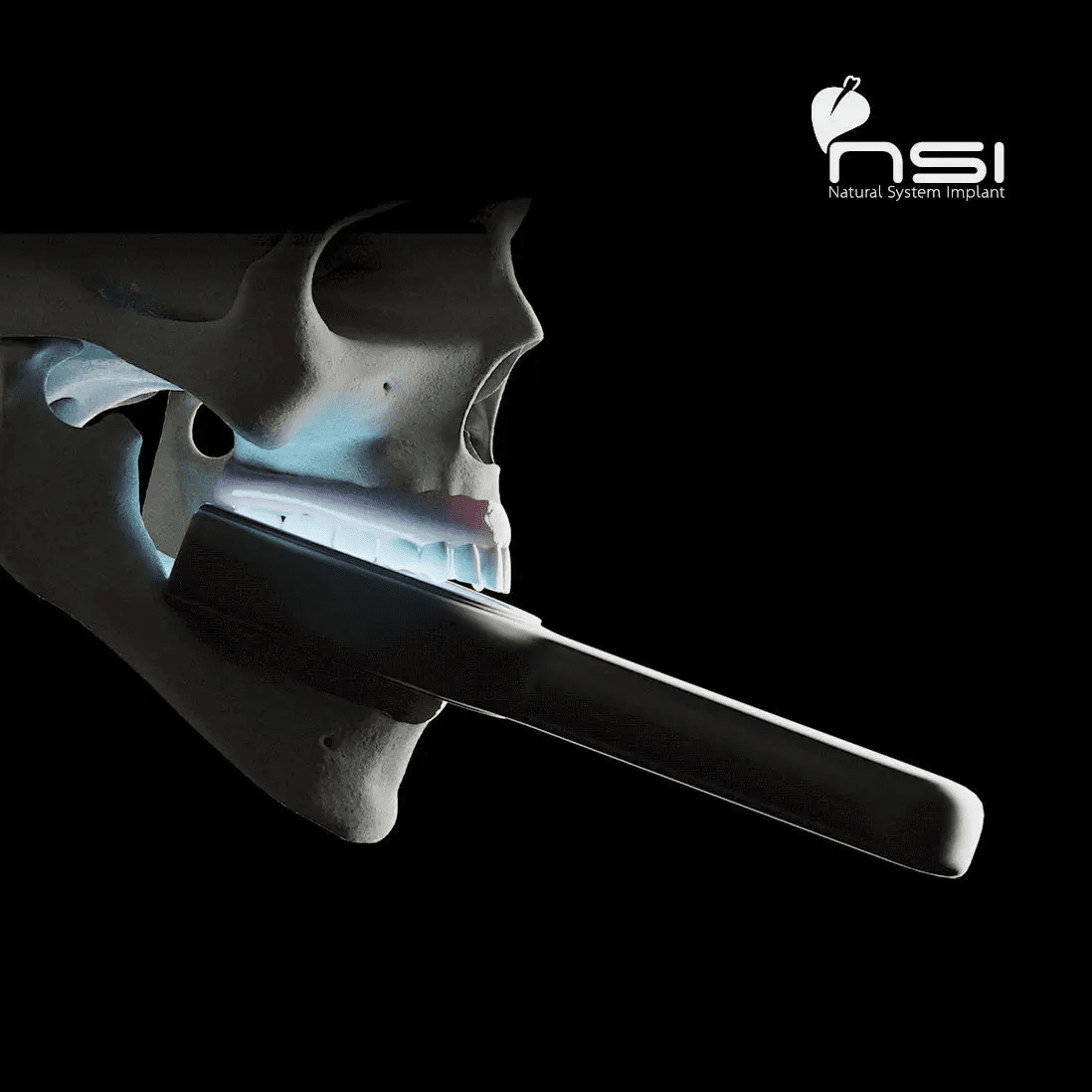

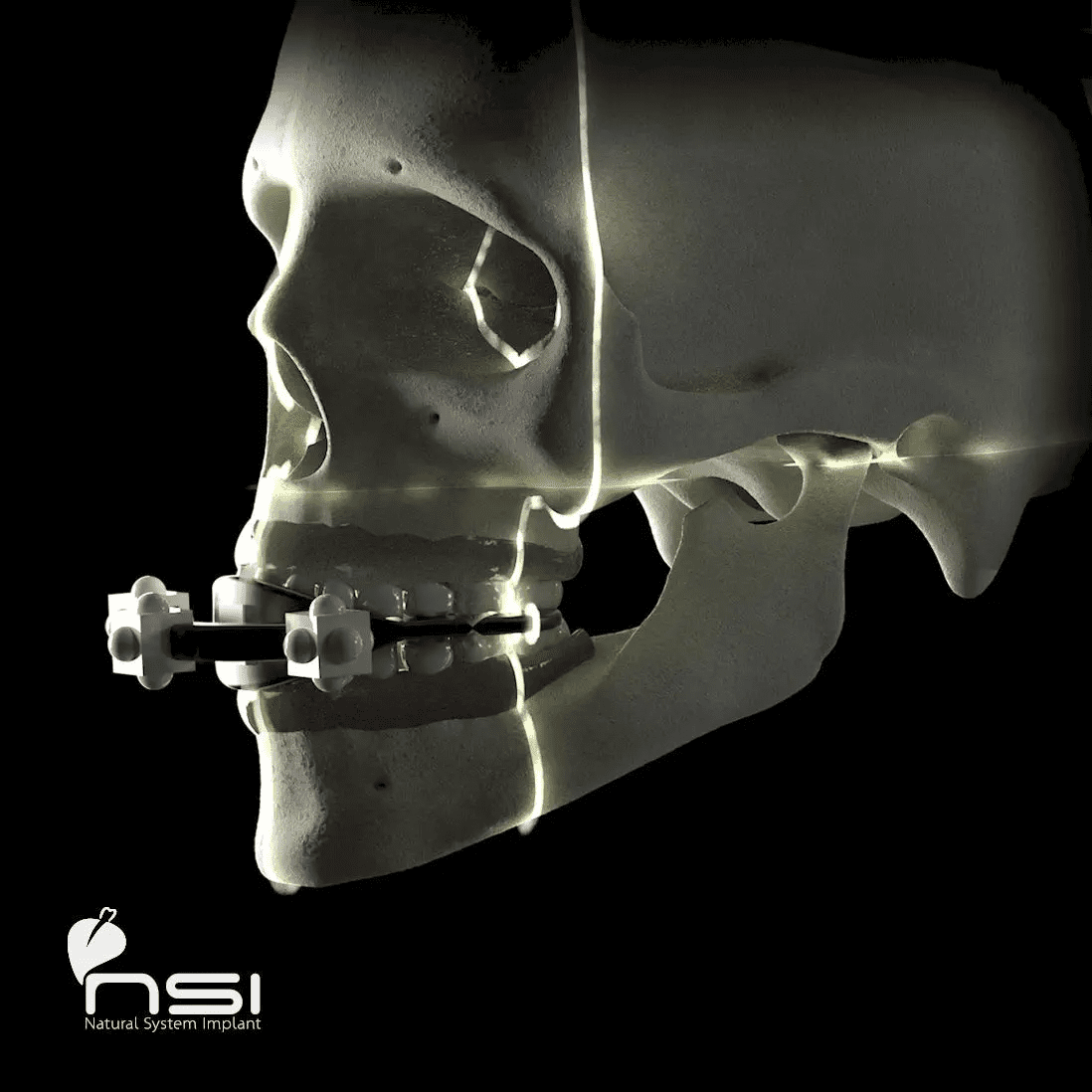

CORTICAL SUPPORT EVEN IN THE MOST DELICATE CONDITIONS

Thanks to the profile of the coils and the patented NSI design, it is possible to exploit the cortices in the most promising areas to allow immediate loading, avoiding problems such as the mandibular nerve or the maxillary sinus.

PRECISION – SAFETY – QUICK TIMES

With a single passage of a ø 2 mm drill, we can insert the implant and guarantee immediate loading in 24 hours.

Thanks to our NSI 3D protocol for planning and manufacturing dental components, the patient will leave the dental office with fixed, temporary, or permanent teeth within 24 hours. In addition, NSI will fully manage the process, from planning to the final tooth.

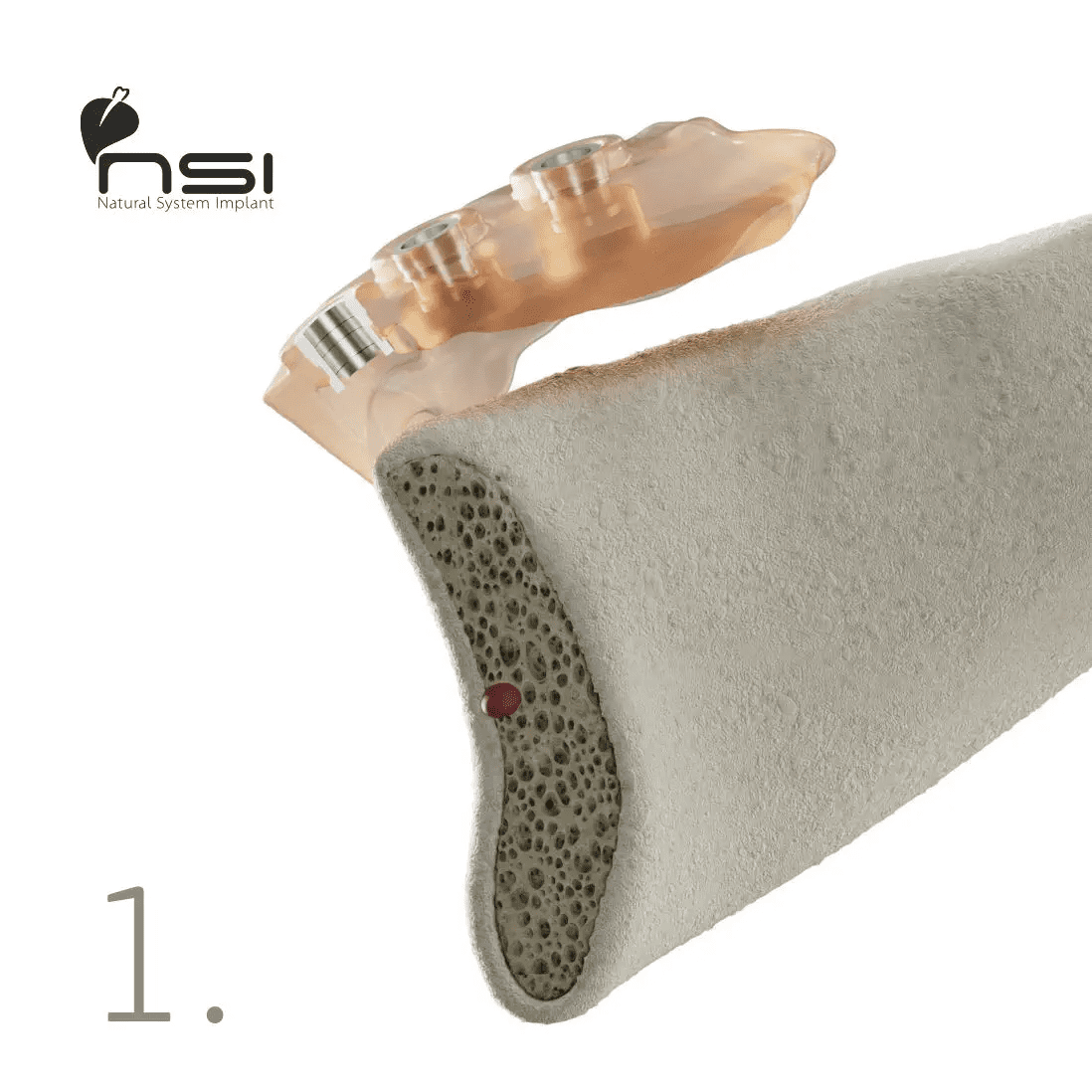

FIRST STEP

- Intraoral Scan

- CT scan and 3D marker

- Matching TAC

- Imprint

- Surgical guide

SECOND STEP

The dentist will receive the kit with the relative devices within 24 hours after approving the planning: study model, surgical guide, temporary elements, monophasic implants to be used.

STEP BY STEP:

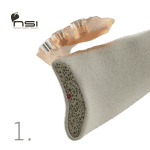

- Surgical template position

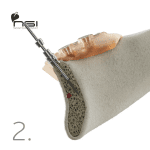

- Insertion of the ø 2 mm drill

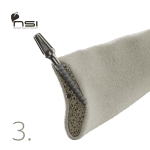

- Single-phase implant insertion

- Bending up to 40°

- Immediate load

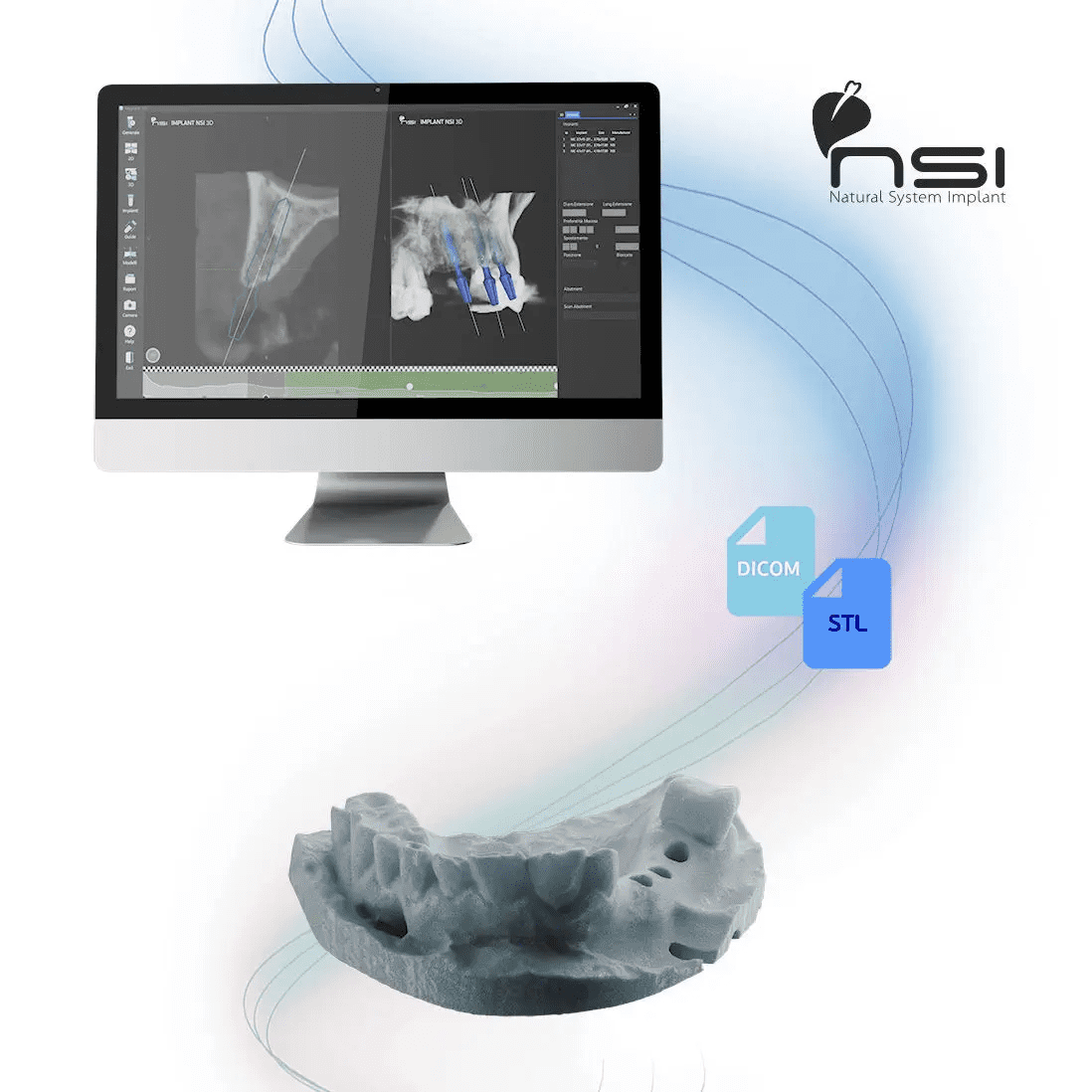

COMPLETE DIGITAL WORKFLOW

Our company and laboratories are entirely digitized to receive DICOM files and STL impressions to develop any prosthetic implant project, from the surgical guide to the bone juxta, including temporary and definitive elements.

FULL-LAB PROSTHESIS SERVICE

You can complete the project by taking advantage of our laboratory for provisionals or fixed prostheses to offer your patient the best service.

AIM: walk out of your studio smiling.

| Applications | for dental implantology |

|---|

Category: Surgical Guide

Close

Categories

Tags

- anatomical

- angled

- bitirme

- conical

- customizable

- cutting

- düz

- dış

- el aleti

- external

- handpiece

- internal

- internal hexagon

- iç

- iç altıgen

- kesme

- konik

- metalik

- metallic

- one-piece

- paslanmaz çelik

- spiral

- spiral

- straight

- taşlama

- tek parça

- titanium

- titanyum

- top

- التشطيب

- التيتانيوم

- الفولاذ المقاوم للصدأ

- بزاوية

- حلزوني

- خارجي

- داخلي

- طحن

- قبضة

- قطع

- قطعه

- كرة

- مخروطي

- مستقيم

- مسدس داخلي

- معدني